I. Definition and Core Characteristics

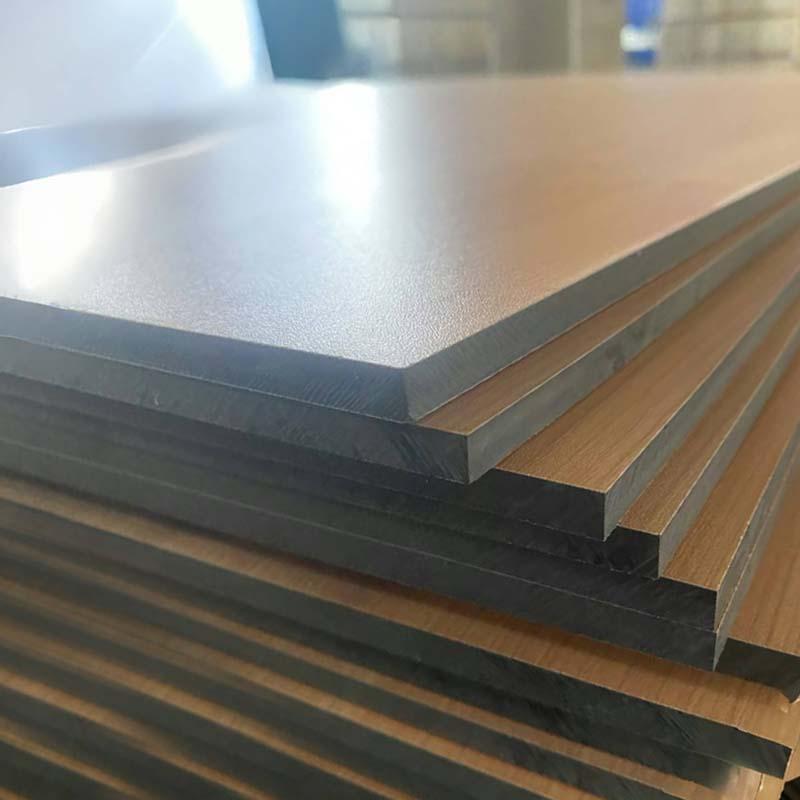

Compact laminate is a type of high-pressure laminate (HPL), formed by stacking multiple layers of kraft paper impregnated with phenolic resin and decorative surface paper, then pressing them under high temperature (over 150°C) and high pressure (1400–1500 PSI) into a solid, monolithic panel. With thicknesses ranging from 1.6mm to 25mm, it offers exceptional high strength, water resistance, fire resistance, abrasion resistance, and corrosion resistance, making it ideal for demanding indoor and outdoor applications.

II. Composition and Structure

Layered Structure:

Surface Layer: Decorative paper (printed with wood, stone, or solid colors) impregnated with melamine resin, providing aesthetic appeal and surface protection.

Core Layer: Multiple layers of kraft paper (or wood pulp paper) impregnated with phenolic resin, forming a high-strength substrate that determines the panel’s mechanical properties.

Process: Bonded into a single piece via continuous hot-pressing, with no glue joints. Density reaches 1.4–1.5g/cm³, with hardness approaching that of steel.

Key Materials:

Resins: Phenolic resin (core layer, for heat and water resistance) + melamine resin (surface layer, for stain resistance and easy cleaning).

Papers: High-quality bleached kraft paper (enhances toughness) or wood pulp paper (controls costs).

III. Core Performance Advantages

Physical Properties:

High Strength: Flexural strength ≥70MPa; impact resistance is 3–5 times that of ordinary panels, suitable for high-load scenarios (e.g., public facilities, load-bearing furniture components).

Dimensional Stability: Water absorption ≤1.5% (after 24-hour immersion); expansion rate in humid heat environments is only 0.1%, resisting deformation and cracking.

Fire Rating: Meets GB 8624-B1 (flame-retardant material) or EN 13501-1-B-s1,d0 (European standard), with no open flame residue from cigarette burns.

Weather and Chemical Resistance:

Waterproof and Moisture-Proof: Solid structure with no pores, suitable for direct contact with water in high-humidity environments like bathrooms, pool areas, and kitchens.

Corrosion Resistance: Resistant to acids and alkalis (e.g., laboratory reagents, cleaning agents), with a surface that is not easily eroded by solvents, ensuring long-term colorfastness and mold resistance.

Environmental and Safety Features:

Formaldehyde Emission: Complies with E0 grade (≤0.05mg/m³) or Japanese F4 Star standard (≤0.3mg/L), safe for indoor use.

Surface Antibacterial: Some brands add antibacterial coatings to inhibit the growth of microbes like E. coli and Staphylococcus aureus (e.g., for medical applications).

IV. Main Application Areas

Architectural Decoration:

Walls/Partitions: Public restroom partitions (moisture and impact resistance), hospital ward partitions (easy to clean, disinfection-resistant), and exterior wall cladding for commercial spaces (outdoor weather resistance).

Countertops: Kitchen countertops (stain and cut resistance), laboratory workbenches (chemical resistance, easy maintenance), and bar/cashier counters (abrasion and load resistance).

Furniture Manufacturing:

Bathroom cabinets, wardrobes, and office furniture (moisture and deformation resistance), especially suitable for humid regions or custom furniture.

Public Facilities:

Interior fittings for subways/high-speed trains (fire and abrasion resistance), school desks and chairs (graffiti resistance, easy cleaning), and outdoor seating (strong weather resistance).

Special Scenarios:

Marine/RV interiors (lightweight, resistant to heat and humidity), industrial equipment casings (impact and corrosion resistance).

V. Specifications and Surface Treatments

Standard Sizes:

Common panels: 1220×2440mm, 1525×3050mm (customizable for oversized dimensions).

Thickness: 1.6mm (for decorative veneers), 3mm–25mm (for structural applications like countertops and partitions).

Surface Finishes:

Glossy, matte, suede, wood/stone/metal textures, with some brands offering embossed textures or anti-fingerprint treatments.